Needlepunch

Needlepunch Advanced Technology

Features

- Capable to handle natural & man-made fibers ((PET, PP, Viscose, Aramids, Carbon, Opan, Acrylic, Wool, P-84, PPS Cotton, etc.)

- On-line & Off-line needle loom combinations deliver high productivity with highest needle density

- Can produce Multi-layered fabric (Up to 4) with & without scrim

Welspun Advanced Textile Solution For Filtration

Welspun Advanced Textile Solution for Composite Industry

Features

- Capable to handle natural & man-made fibers ((PET, PP, Viscose, Aramids, Carbon, Opan, Acrylic, Wool, P-84, PPS Cotton, etc.)

- On-line & Off-line needle loom combinations deliver high productivity with highest needle density

- Can produce Multi-layered fabric (Up to 4) with & without scrim

Welspun Advanced Textile Solution For Fire & Safety

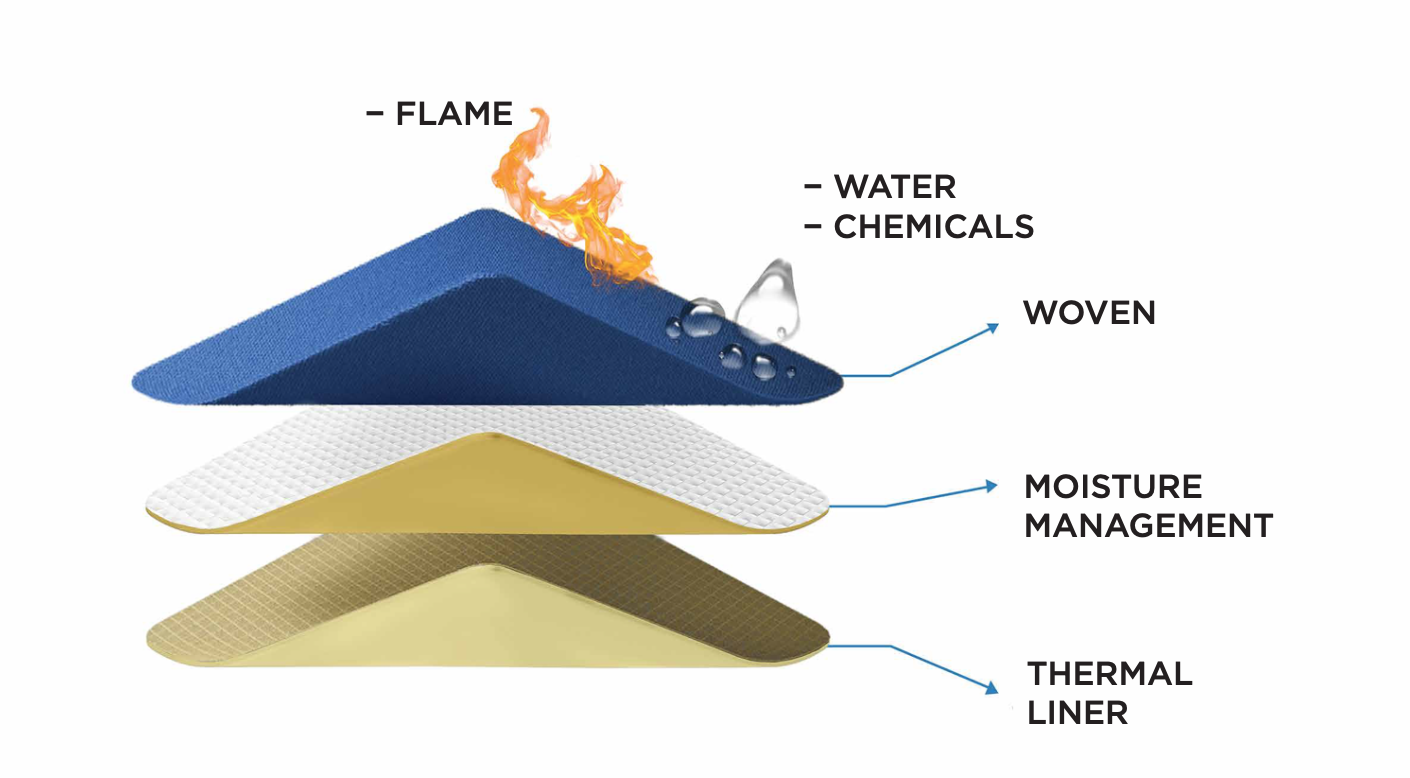

Products for Turnout Gear/ Bunker Gear

Moisture Barrier

Thermal Liner

This is the innermost layer of the turnout gear’s composite system made out of inherent FR aramid fiber & blends hybrid technology (Needlepunch+Spunlace) in plain, aperture & 3D embossed structure. This high strength to weight ratio non-woven fabric layer provides better insulation and thermal resistance properties with excellent wash fastness making it an alternate option to commodity FR woven fabric.

Products for Arc Flash Clothing

Inherent FR nonwoven liner is used as an inner shell in HRC 3 (Category 3) & HRC 4 (Category 4) Arc protection garments to protect electrical workers from arc & flash fire hazards. Compliant to EN469 & NFPA 70-E standard, this light weight 3D hybrid fabric provides better insulation, superior arc protection, excellent wear comfort and wash fastness & durability.

Products for Fire Blanket

Products for Fire Barrier for Upholstery & Mattress

Low to High GSM inherent FR fiber based Needlepunched nonwoven fabric meeting EN 45545, EN BS 5852 (Match & Cigarette test) & 16 CFR part 1633 California standard. Fire barrier is used in railway and aircraft seat as an interliner between the top fabric and the foam, FR barrier layer for mattress and upholstery.